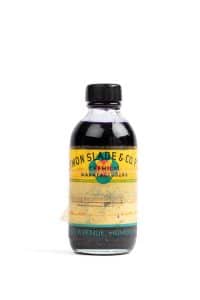

W. Hermon Slade/Polymer – Industrial Chemists

W. Hermon Slade and Homebush West, c.1940s by Milton Kent. Courtesy State Library of NSW

Have you found time to visit the Minding Our Business: Strathfield’s Industrial Heritage exhibition at Strathfield Library’s Ironbark Gallery yet?

One of the businesses featured is that of W. Hermon Slade, industrial chemists.

William Hermon Slade began as a produce, and later, hardware merchant.[1] Son, George Hermon (known as Hermon) was born in 1910 and William Russell (known as Russell) in 1914. After travelling overseas post-WWI, Hermon senior began business as a wholesale druggist, soon supplying Washington H. Soul’s pharmacies.[2] He was so successful that it was suggested that he begin manufacturing drugs in Australia, which he did. With a love of industrial science, Hermon junior also became involved with the pharmaceutical manufacturing at Rosebery. Depression-era was tough. Hermon senior was also busy as a director and general manager of the ailing Bonds company. Later he was chairman as well.[3]

A chance meeting with Paul Wagner of the German firm, Theo Goldschmidt AG, led to further diversification for the Slades. Young Hermon succeeded in perfecting the process for manufacturing the emulsifier, glycerol monostearate in Australia for the cosmetics industry. A non-toxic vegetable wax, it was a boon to the industry for many products. Soon, Slade began experimenting with industrial products such as ester gum for the paint industry.[4]

In 1943, during WWII, Slade (also known as Polymers Pty Ltd) relocated their factory from Rosebery to Flemington (Homebush West). The 33-acre site had previously been used as a brickworks and then as storage for American torpedoes and bombs – in its conveniently huge, water-filled pit. The property was purchased from Brickworks Ltd for the sum of 26,000 pounds.

Among Slade’s valuable contributions to the war effort was Tego Gluefilm, a waterproof polymer that could forge multiple layers of timber into a strong, flexible product used in army huts, motor launches and barges. From 1943 it was also used in the body and wings of the Mosquito bomber.

Other useful chemicals manufactured included dibutyl phthalate (known as ‘Betty’) – a plasticising material for enhancing the flexibility of lacquers – but also with potential as a stabiliser for the explosive material, cordite. By July 1943, Slade was making 3600 pounds per day.[5]

Another desperate wartime need was for products to control the mosquitoes and constant threat of malaria in New Guinea. Slade was asked to trial a number of potential products to assist. The problem was solved with the production of dimethyl phthalate (known as ‘Mary’) which had the added benefit of being almost odourless and non-irritating to the skin. it was in general use by Australian forces by the end on 1943 and was later also used by American forces. When added to clothing, dibutyl phthalate could also repel and kill the mite that carried the fatal scrub typhus. ‘Betty’ and ‘Mary’ became top-secret weapons of war. Slade also invented glycerol trioleate, a substitute for the olive oil critical in the wool industry, but in short supply during the war.[6]

Other innovations included Tegin glycerol monostearate, an emulsifier which was successfully trialled in ice-cream production with Peters and was also useful in the bread and confectionery industries.[7]

After the war there was demand for polyvinyl chloride (PVC) and Slade was the only Australian producer of dioctyl phthalate, the most important plasticiser for the plastics industry. By 1947 Slade had three major product types – emulsifiers for food, textiles and cosmetics; synthetic resins for paints; and plasticisers for lacquers and plastics.[8]

A shortage of components meant that the production of some products had to cease in mid-1947. At that time Slade was the only NSW manufacturer of varnish resins but a shortage of caustic soda to make the phenol necessary for production meant that varnish resin could not be made. When the components were available the factory could manufacture four tons of varnish a day. With this, paint makers could produce 20 tons of paint – enough for 600 cottages.[9] By 1954 Australian paint companies required 40 million pounds of resin and the Slades produced 50 different types.[10]

From the late 1940s the factory was a haven for European workers displaced by war. ‘To promote easy communication in the factory, there were three production shifts, organised according to the native language of the workers – English, German and the Slavic tongues of Central Europe.’[11]

Accidents were not uncommon. In 1951 two men were injured when a 44-gallon drum of explosives blew up. The lid of the 30 foot vat threw one of the men into the air, and he hit his head on the ceiling.[12][13] In 1954 two men were badly burned when a vat of resin boiled over.[14]

Another Australian first was achieved in 1953 when Slade began producing nylon as polyamide filaments for brushes and fishing lines. One variety of polyamide resin was used to hold the many thousands of tiles on the Sydney Opera House.[15] Two new products were used in fibreglass construction and the company also moved into the paper coating industry. Slade even produced a water-based sealer to hold in place the cellophane wrapping at the end of every packet of Arnott’s SAOs.

Staff Christmas parties were held in the gardens at Homebush with vast quantities of prawns. Each employee went home with a ham. The Slade family took great interest in their employees, sometimes providing personal guarantees for loans.

Accelerator C, produced by W. Hermon Slade and donated to the Powerhouse Museum in 1954.

https://collection.maas.museum/object/242711

During the late 1960s the business was sold, initially to the US General Mills Company, famous for its Betty Crocker range of products. But it was quickly sold again to Australian Chemical Holdings (ACH).[16] The Slade brothers went on to pursue their love of philanthropy and research. Today, the Hermon Slade Foundation awards grants for biological research.[17]

ACH continued in business at Homebush until December 1993. New apartments in Courallie Avenue now stand on this site.

Discover more about our local industries in the Minding Our Business: Strathfield’s Industrial Heritage exhibition at the Ironbark Gallery, Strathfield Library from 12 July to 14 August. A talk will be held on Sunday 31 July. Bookings are essential and can be made at: https://www.eventbrite.com.au/e/talk-on-industrial-heritage-of-strathfield-exhibition-tickets-354877467057?aff=ebdssbdestsearch

By J.J. MacRitchie

References

[1] Todd, Jan The Polymer Story: a family’s journey in Australian chemical science. Mona Vale, NSW: Hermon Slade Raiatea Foundation. p.2[2] ibid p.3

[3] ibid p.12

[4] ibid p.19

[5] ibid p.24

[6] ibid pp.24-28

[7] ibid pp.41-42

[8] ibid p.46

[9] Sydney Morning Herald 7 August 1947 p.4 https://trove.nla.gov.au/newspaper/article/27894627

[10] Todd, p.57

[11] Todd p.53

[12] Sydney Morning Herald 13 November 1951 p.3 https://trove.nla.gov.au/newspaper/article/18239123

[13] The Daily Telegraph 13 November 1951 p.7 http://trove.nla.gov.au/newspaper/article/248697928

[14] Brisbane Telegraph 26 February 1954 p.40 https://trove.nla.gov.au/newspaper/article/217208893

[15] Todd. p.87

[16] Todd pp.133-135

[17] http://www.hermonslade.org.au/

1 Comment. Leave new

My father worked at Hermon slade in early 1950 till his retirement. He was a doctor previously but was not recognised in Australia. I think the government of the time sent him to work there. We came to Sydney on armictice day in 1949 at 11am.